"Vizag Steel: Powering Nation’s Growth"

The Visakhapatnam Steel Plant has firmly established itself as an iconic industrial landmark, playing a crucial role in the steel sector and the economic development of the region. Over the years, it has grown into a key player in the steel industry, producing high-quality products for both the domestic and international markets. With its ongoing emphasis on innovation, technological advancement, and environmental sustainability, VSP is poised to remain a significant force in the global steel industry for many years to come.

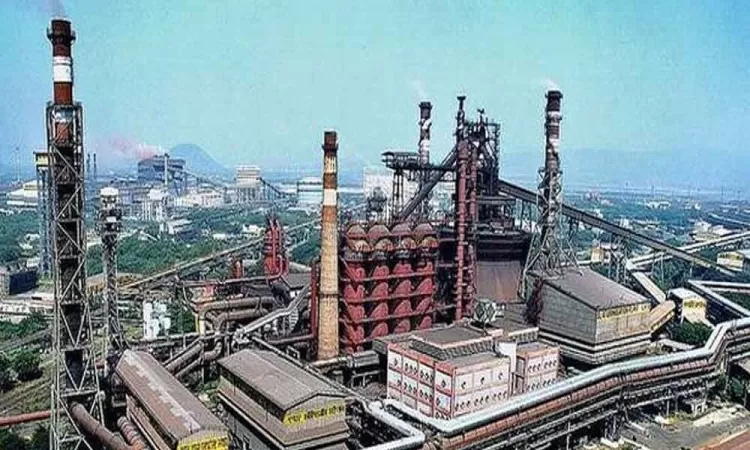

The Visakhapatnam Steel Plant (VSP), also referred to as Vizag Steel, stands as one of India’s premier integrated steel production facilities, located in Visakhapatnam, Andhra Pradesh. Established by Rashtriya Ispat Nigam Limited (RINL), the plant has been a significant contributor to India’s industrial growth, particularly in the steel sector. Over the years, it has become a symbol of industrial excellence and has played a vital role in the socio-economic development of the region.

Historical Background

The groundwork for the Visakhapatnam Steel Plant was laid in 1971. Recognizing the importance of steel in industrial advancement, the Indian government decided to establish a state-owned steel plant in the strategically located coastal city of Visakhapatnam. This location offered advantages such as proximity to the sea for importing raw materials and exporting finished products, along with access to a skilled workforce. After years of meticulous planning and development, the plant commenced operations in 1992.

Key Features and Infrastructure

The Visakhapatnam Steel Plant ranks among the largest steel producers in India, boasting an annual production capacity of approximately 7.3 million tons of liquid steel. The plant uses an integrated manufacturing process, converting raw materials like iron ore, coal, and limestone into steel through various stages. It is equipped with cutting-edge facilities, such as blast furnaces, coke ovens, sintering plants, steel melting shops, and rolling mills, all of which work together to produce high-quality steel.

With a robust infrastructure and modern technologies, the plant enhances productivity while minimizing environmental impact. It produces a wide range of products, including hot-rolled coils, cold-rolled coils, wire rods, bars, and structural steel, which find applications across sectors like construction, automotive, energy, and infrastructure.

Strategic Location and Connectivity

The strategic location of the Vizag Steel Plant offers numerous advantages. Situated on the east coast of India, it enjoys excellent connectivity by sea, road, and rail. The presence of a major seaport in Visakhapatnam facilitates the import of raw materials such as coal and iron ore from countries like Australia, South Africa, and Indonesia. The plant’s location also allows it to efficiently access global markets for its finished steel products, enhancing India’s presence in the international steel market.

In addition to its maritime advantages, the city is well-connected by national highways and a strong rail network, ensuring seamless transportation of raw materials to the plant and optimizing supply chain efficiency.

Economic Significance

The Visakhapatnam Steel Plant is not just an industrial hub; it is also a key contributor to the economic growth of both the region and the nation. The plant provides direct and indirect employment to thousands of people and makes a substantial contribution to the GDP of Andhra Pradesh. Its operations also support the growth of related industries, including coal and iron ore mining, logistics, and transportation.

In addition to serving the domestic market, VSP has made its mark on the global steel industry. Its products are exported to over 30 countries, including the USA, the Middle East, and Southeast Asia. This international presence has reinforced India’s position as one of the world’s top steel producers.

Technological Advancements and Environmental Sustainability

Visakhapatnam Steel Plant is renowned for its commitment to adopting advanced technologies and modernizing its operations. The plant has embraced automation and cutting-edge manufacturing techniques to improve efficiency, lower production costs, and maintain superior quality standards.

From an environmental sustainability perspective, VSP has taken several steps to minimize the ecological footprint of steel production. The plant has implemented systems for recycling waste, treating water, and managing emissions. Additionally, eco-friendly technologies, such as waste heat recovery and efforts to reduce CO2 emissions, demonstrate the plant’s dedication to sustainability and reducing its environmental impact.

Challenges and Future Prospects

Despite its achievements, the Visakhapatnam Steel Plant has faced challenges over the years, including fluctuations in global steel prices, variations in raw material costs, and changes in government policies. However, the plant has responded by investing in modernization and expanding its production capacity to remain competitive in the global market.

Looking ahead, the plant is focused on further increasing its production capacity and becoming a fully integrated, modern steel producer. This growth aligns with India’s broader goals, including the “Make in India” initiative, which is expected to boost domestic steel consumption and offer new opportunities for the plant.

What's Your Reaction?