The Chocolate Factory: From Bean to Bar...!!!

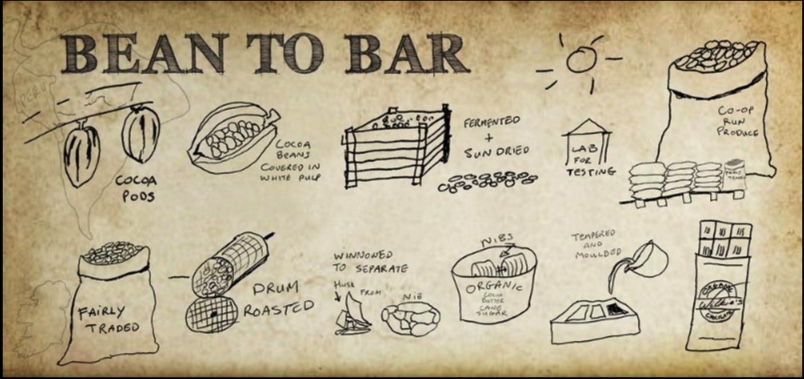

A chocolate factory is a place of craftsmanship and precision, where the journey from cocoa bean to chocolate bar unfolds through a series of meticulous steps. From the careful harvesting and fermentation of cocoa beans to the artful tempering and molding of chocolate, each stage plays a vital role in creating the delectable treat that we all cherish.

A chocolate factory is a mesmerizing place where raw cocoa beans are transformed into delectable chocolate bars and confections. The process of making chocolate involves several intricate steps, each contributing to the rich flavor and smooth texture of the final product. Here, we explore the journey of chocolate production, from the harvesting of cocoa beans to the packaging of the finished product.

1. Sourcing and Harvesting Cocoa Beans

The journey of chocolate begins with the sourcing of cocoa beans. Cocoa trees (Theobroma cacao) thrive in tropical climates near the equator, with major producers including countries like Ivory Coast, Ghana, Indonesia, and Brazil. Farmers harvest cocoa pods by hand, carefully cutting them from the trees with machetes.

Once harvested, the pods are opened to reveal the cocoa beans surrounded by a sweet, sticky pulp. The beans and pulp are scooped out and placed in shallow containers or covered with banana leaves for fermentation. This crucial step lasts several days and helps develop the beans' flavor. During fermentation, the pulp breaks down, and the beans undergo a series of chemical changes.

2. Drying and Roasting

After fermentation, the beans are spread out in the sun to dry. This drying process can take up to a week and reduces the moisture content of the beans, making them suitable for storage and transport. Once dried, the beans are packed into bags and shipped to chocolate factories around the world.

At the factory, the beans undergo roasting, essential for developing the characteristic chocolate flavor. Roasting times and temperatures vary depending on the type of bean and the desired flavor profile. The beans are roasted at temperatures ranging from 250 to 350 degrees Fahrenheit (120 to 180 degrees Celsius) for 30 minutes to two hours.

3. Cracking and Winnowing

Following roasting, the beans are cracked open to separate the outer shell from the inner nib. This process, known as winnowing, involves passing the beans through a series of machines that crack and blow away the lighter shells, leaving the nibs behind. The nibs are the edible part of the cocoa bean and the primary ingredient in chocolate.

4. Grinding and Conching

The nibs are then ground into a thick paste called cocoa mass or chocolate liquor. This grinding process generates heat, causing the fat (cocoa butter) in the nibs to melt and form a liquid. The chocolate liquor can be further processed into cocoa powder and cocoa butter.

To create smooth and creamy chocolate, the chocolate liquor undergoes conching. Conching is a mechanical process that involves continuously mixing, kneading, and aerating the chocolate liquor for several hours to several days. This process refines the texture and enhances the flavor by allowing volatile acids to evaporate and the cocoa butter to distribute evenly.

5. Tempering and Molding

Tempering is a crucial step in chocolate production that ensures the finished chocolate has a glossy appearance and a satisfying snap. During tempering, the chocolate is carefully cooled and reheated to specific temperatures to form stable cocoa butter crystals. This process prevents the chocolate from developing a dull, grainy texture.

Once tempered, the chocolate is poured into molds to create bars, tablets, or various shapes. The molds are gently tapped to remove any air bubbles and ensure an even distribution of chocolate. The molds are then cooled to allow the chocolate to solidify and take its final shape.

6. Packaging and Distribution

After the chocolate has fully cooled and solidified, it is removed from the molds and packaged. Packaging not only protects the chocolate from damage and contamination but also provides essential information about the product, such as ingredients, nutritional content, and expiration date.

The packaged chocolate is then ready for distribution. It is shipped to retailers, wholesalers, and consumers worldwide, bringing joy and indulgence to chocolate lovers everywhere.

A chocolate factory is a place of craftsmanship and precision, where the journey from cocoa bean to chocolate bar unfolds through a series of meticulous steps. From the careful harvesting and fermentation of cocoa beans to the artful tempering and molding of chocolate, each stage plays a vital role in creating the delectable treat that we all cherish. Whether enjoyed as a simple bar or a complex confection, chocolate remains a timeless delight that continues to captivate our senses.

What's Your Reaction?