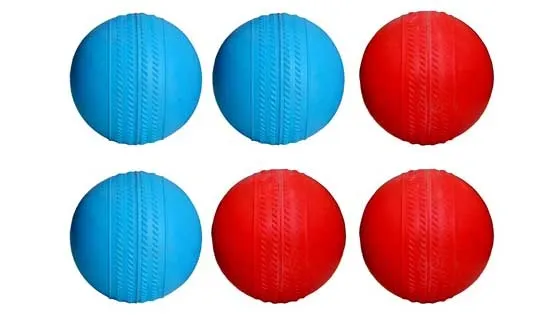

Rubber Balls: Production and Applications...!!!

Rubber balls are versatile products with a broad range of applications in toys, sports, industry, medicine, and consumer goods. Their manufacturing process involves several steps, including compounding, molding, vulcanization, and finishing, to ensure high-quality standards.

Rubber balls are integral to many aspects of our daily lives, with uses ranging from children's toys to industrial components.

Production of Rubber Balls

1. Raw Materials

-

Natural Rubber: Extracted from the latex of rubber trees (Hevea brasiliensis), natural rubber is valued for its elasticity and resilience.

-

Synthetic Rubber: Created from petroleum-based chemicals, synthetic rubber provides enhanced properties such as resistance to heat, chemicals, and wear.

2. Rubber Preparation

-

Compounding: Both natural and synthetic rubber are blended with additives to improve their properties. These additives may include fillers (like carbon black), vulcanizing agents (like sulfur), accelerators, and stabilizers.

-

Mastication: The rubber mixture is mechanically worked to reduce its viscosity, making it easier to process. This involves passing the rubber through heavy rollers to break down its molecular structure.

3. Molding and Shaping

-

Extrusion: The rubber compound is extruded into cylindrical shapes, forming the basic structure of the ball.

-

Molding: The extruded rubber is placed into molds to shape it. Techniques include:

-

Compression Molding: The rubber is placed in a heated mold, and pressure is applied to shape it.

-

Injection Molding: The rubber is injected into a mold cavity under high pressure.

-

Transfer Molding: Similar to injection molding, but the rubber is pre-measured and transferred into the mold cavity.

-

4. Vulcanization

-

Process: The molded rubber is heated with sulfur or other vulcanizing agents, forming cross-links between the rubber molecules to enhance strength, elasticity, and durability.

-

Curing: Post-vulcanization, the rubber balls are cured at a specific temperature for a set period to stabilize their properties.

5. Finishing

-

Trimming: Excess rubber from molding is trimmed off to create a smooth surface.

-

Surface Treatment: Additional treatments such as painting, polishing, or coating can be applied to improve the appearance and performance of the rubber balls.

6. Quality Control

-

Inspection: Finished rubber balls are inspected for defects and tested for properties like bounce, hardness, and uniformity.

-

Packaging: The rubber balls are packaged according to their intended use and market requirements.

Applications of Rubber Balls

1. Toys and Recreation

-

Bouncing Balls: Popular toys for children, rubber balls are known for their high bounce and durability, available in various colors, sizes, and designs.

-

Sports Equipment: Essential in sports like basketball, handball, racquetball, and squash, rubber balls provide the necessary bounce and grip.

2. Industrial Applications

-

Seals and Gaskets: Rubber balls serve as sealing components in industrial machines and equipment, providing tight and flexible seals.

-

Bearings and Rollers: Used as bearings in conveyor systems and rollers in printing machines, rubber balls help reduce friction and wear.

3. Medical and Laboratory Uses

-

Medical Devices: Rubber balls are utilized in medical devices like pumps, valves, and catheters for precise control and flexibility.

-

Laboratory Equipment: In laboratories, rubber balls are employed in pipettes, dispensers, and other equipment for accurate liquid handling.

4. Consumer Goods

-

Household Items: Found in stress balls, massage tools, and exercise equipment, rubber balls offer comfort and resilience.

-

Automotive Applications: In automobiles, rubber balls are used in suspension systems and as dampers to absorb shock and reduce vibration.

Rubber balls are versatile products with a broad range of applications in toys, sports, industry, medicine, and consumer goods. Their manufacturing process involves several steps, including compounding, molding, vulcanization, and finishing, to ensure high-quality standards. Understanding the production and uses of rubber balls underscores their importance in various facets of life.

What's Your Reaction?