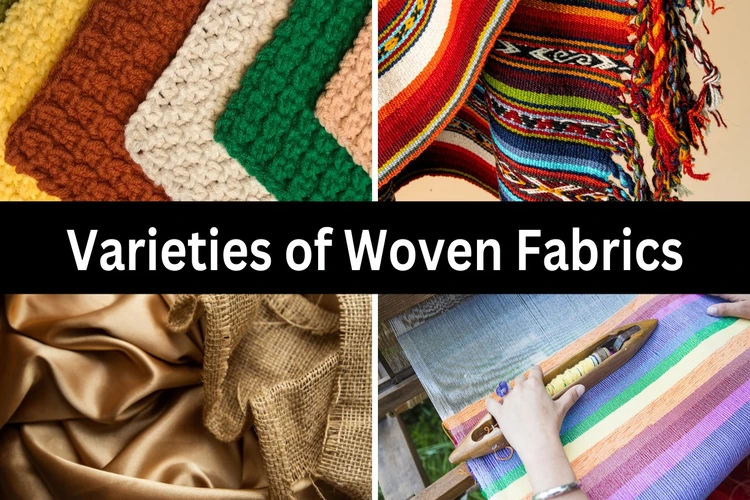

Fabrics Unveiled: Understanding the Varieties and Their Creation Processes...!!!

Each type of fabric offers a distinct set of qualities, making them suitable for various clothing applications. From the natural comfort of cotton and linen to the luxurious feel of silk and the durability of polyester, each fabric type has a unique production process that defines its characteristics. Understanding these processes allows for informed choices about clothing and an appreciation for the craftsmanship involved in fabric production.

1. Cotton

Characteristics:

- Soft, breathable, and absorbent.

- Versatile and comfortable.

Production:

- Growing: Cotton is grown in warm climates.

- Harvesting: The cotton fibers are collected from the plants.

- Ginning: The fibers are separated from the seeds.

- Spinning: The fibers are spun into yarn.

- Weaving/Knitting: The yarn is woven or knitted into fabric.

- Finishing: The fabric is bleached, dyed, and finished to enhance its properties.

2. Silk

Characteristics:

- Smooth, luxurious, and lightweight.

- Shiny appearance with excellent drape.

Production:

- Sericulture: Silk is produced by silkworms that feed on mulberry leaves.

- Reeling: The silk fibers are carefully unwound from the cocoons.

- Spinning: The raw silk fibers are spun into yarn.

- Weaving: The silk yarn is woven into fabric using traditional or modern looms.

- Finishing: The fabric undergoes finishing processes like dyeing and printing.

3. Wool

Characteristics:

- Warm, insulating, and durable.

- Elastic and naturally flame-resistant.

Production:

- Shearing: Wool is obtained by shearing sheep.

- Cleaning/Scouring: The wool is cleaned to remove impurities.

- Carding: The wool fibers are disentangled and aligned.

- Spinning: The carded wool is spun into yarn.

- Weaving/Knitting: The yarn is woven or knitted into fabric.

- Fulling/Finishing: The fabric is treated to enhance its texture and strength.

4. Linen

Characteristics:

- Lightweight, breathable, and absorbent.

- Known for its crisp texture.

Production:

- Growing: Linen is derived from the fibers of the flax plant.

- Harvesting: The flax plants are harvested.

- Retting: The plants are soaked to loosen the fibers.

- Breaking/Scutching: The woody stems are broken to release the fibers.

- Hackling: The fibers are combed to remove short strands.

- Spinning: The long fibers are spun into yarn.

- Weaving: The yarn is woven into linen fabric.

- Finishing: The fabric is bleached, dyed, and finished.

5. Polyester

Characteristics:

- Durable, wrinkle-resistant, and quick-drying.

- Versatile and easy to care for.

Production:

- Polymerization: Polyester is a synthetic fabric made from petrochemicals.

- Spinning: The polymer is melted and extruded into fibers.

- Drawing: The fibers are stretched to align the molecules.

- Spinning: The fibers are spun into yarn.

- Weaving/Knitting: The yarn is woven or knitted into fabric.

- Finishing: The fabric is dyed and finished to enhance its properties.

6. Rayon

Characteristics:

- Soft, smooth, and highly absorbent.

- Mimics the properties of natural fibers like silk and cotton.

Production:

- Cellulose Extraction: Rayon is made from cellulose, often derived from wood pulp.

- Dissolving: The cellulose is dissolved to create a viscous solution.

- Spinning: The solution is extruded through spinnerets to form fibers.

- Regenerating: The fibers are chemically treated to regenerate cellulose.

- Spinning: The fibers are spun into yarn.

- Weaving/Knitting: The yarn is woven or knitted into fabric.

- Finishing: The fabric undergoes finishing processes like dyeing and printing.

Each type of fabric offers a distinct set of qualities, making them suitable for various clothing applications. From the natural comfort of cotton and linen to the luxurious feel of silk and the durability of polyester, each fabric type has a unique production process that defines its characteristics. Understanding these processes allows for informed choices about clothing and an appreciation for the craftsmanship involved in fabric production.

What's Your Reaction?